Basic HTML Version

5/22

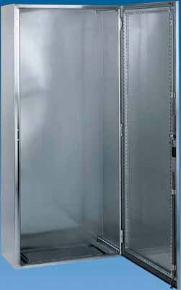

floor-standing enclosures

Introduction

Specific

Technical characteristics

These enclosures have been specially designed for the chemical, oil and food

and beverage industries, among others, which are particularly demanding in

terms of hygiene and resistance to corrosion.

● Stainless-steel sheet floor-standing enclosure, 1.5 mm thick, folded and welded.

● Two types of materials, with Scotch-Brite

®

brushed finish, are available:

– 304L stainless steel,

– 316L stainless steel.

● Micro-beaded and painted finishes (on request).

● Protection rating: IP 55 according to IEC 60529.

● 1 Nema door, type 1, 2, 3, 3R, 4, 4X, 5, 12, 12K, 13.

● 2 Nema doors, type 1, 2, 12K.

● Resistance to external mechanical impacts: IK 10 according to IEC 62262.

● Plain front door. Opening to left or right to 120° with reinforcement frame. Installed

on 3 stainless-steel hinges. 3-point closure with handle made from painted zamak,

5-mm double bar.

Acceptable load of 50 kg.

● Delivered with 4 mounting plate-supporting brackets.

● Single-piece cable-gland plate delivered.

● 316L stainless-steel plinths, optional heights of 100 and 200 mm.

● Optional stainless-steel canopies.

● Optional eyebolts.

Maximum load: 830 kg when slinging at 60º.

● For more information on the technical features of the different types of finishes:

see page

5/5

.

Certifications

● IEC 62208.

● UL 508.

● CAN/CSA 22.

External dimensions (mm)

Number

of front

doors

Stainless-steel

floor-standing

enclosure

304L / 316L*

Brushed 316L stainless-steel plinth

height 100 mm **

Brushed 316L stainless-steel plinth

height 200 mm **

Plain mounting

plate ***

Height

Width

Depth

Front + corner

Side

Front + corner

Side

1400

1000

300

2

NSYSMX141030 NSYSPXF10100H NSYSPXS3100H NSYSPXF10200H

2

NSYSPXS3100H NSYMP1410

1600

800

400

1

NSYSMX16840 NSYSPXF8100H NSYSPXS4100H NSYSPXF8200H

2

NSYSPXS4100H NSYMP168

1800

600

400

1

NSYSMX18640 NSYSPXF6100H NSYSPXS4100H NSYSPXF6200H

2

NSYSPXS4100H NSYMP186

1800

800

400

1

NSYSMX18840* NSYSPXF8100H NSYSPXS4100H NSYSPXF8200H

2

NSYSPXS4100H NSYMP188

1800

1200

400

2

NSYSMX181240* NSYSPXF12100H NSYSPXS4100H NSYSPXF12200H

2

NSYSPXS4100H NSYMP1812

1800

1600

400

2

NSYSMX181640* NSYSPXF16100H NSYSPXS4100H NSYSPXF16200H

2

NSYSPXS4100H NSYMP1813

2000

800

500

1

NSYSMX20850 NSYSPXF8100H NSYSPXS5100H NSYSPXF8200H

2

NSYSPXS5100H NSYMP208

2000

1000

400

2

NSYSMX201040* NSYSPXF10100H NSYSPXS4100H NSYSPXF10200H

2

NSYSPXS4100H NSYMP2010

2000

1200

500

2

NSYSMX201250* NSYSPXF12100H NSYSPXS5100H NSYSPXF12200H

2

NSYSPXS5100H NSYMP2012

2000

1600

600

2

NSYSMX201660* NSYSPXF16100H NSYSPXS6100H NSYSPXF16200H

2

NSYSPXS6100H NSYMP2016

* For version in AISI 316L stainless steel, add the lettre H to the end of the reference. Example NSYSMX18840H

**See section on stainless-steel composition accessories.

***See other mounting plates in common accessoires.

05_022_023_SMX002.indd 22

28/1